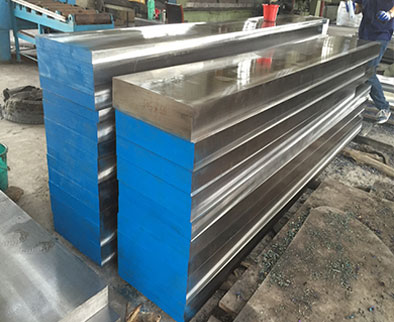

Supply High Quality Mold Steel Products

Committed to providing high quality hot work mold steel, cold work mold steel and plastic mold steel.

Cold work die steel refers to the die steel that metal is deformed or shaped into under cold condition.

Hot work die steel refers to alloy tool steel suitable for making molds for metals hot deformation.

Plastic die steel is a mold steel used in plastics making. The development of die steel promotes the.